Process solutions for the manufacturing industry

Tebis AG is a leading global provider of CAD/CAM and MES software. With high degree of expertise in consulting, implementation and support, they’ve been implementing highly efficient and reliable process solutions for their customers for over 35 years. Customers use Tebis solutions to manufacture single parts like models, molds and dies as well as the highest-quality series parts made of metal or plastic.

Tebis’ customers are among the most coveted partners in the global automotive, aerospace and production machining industries.

The clients of Tebis customers also include companies from the motorsports, energy, agricultural machinery and medical technology industries as well as the consumer goods sector.

If machines were to decide…

… they’d choose NC programs from Tebis!

Machines love Tebis because they manufacture masterpieces in record time while avoiding collisions. The most automotive manufacturers worldwide are using Tebis.

Manufacture high-quality parts efficiently and reliably!

Benefit from Tebis

High quality

- Manufacture higher-quality parts

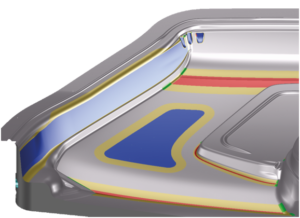

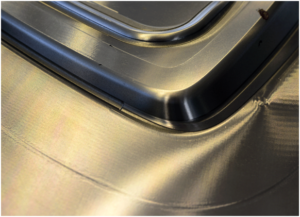

- Highest Class-A quality in finished parts

- High-performance surface calculations

- Highly sensitive algorithm for distributing NC points on NC paths

Efficient

- Manage manufacturing projects more efficiently

- Quickly import geometry through interfaces

- Save time in designing, repairing and preparing surfaces

- Fast NC programming

- Less manual reworking

Reliable

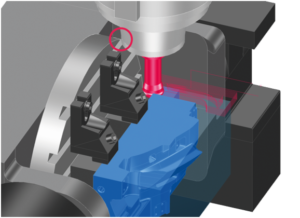

- Make machine operators’ workplaces safer

- Better protect machines and workpieces

- Simulation of the real manufacturing environment with process libraries

- Detect collisions and limit switch conflicts in the CAM programming environment

Better organize and optimize CAD/CAM process chains. Twelve key Tebis strengths.

- Many manufacturing methods – one software solution

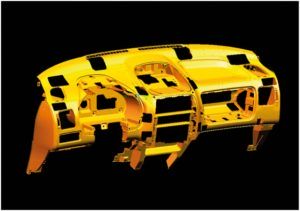

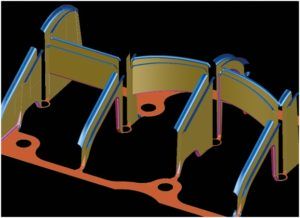

- A passion for large parts and complex geometries

- First-class interfaces

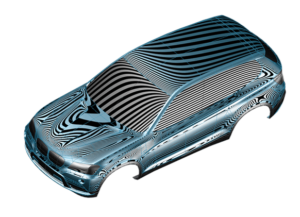

- Top technology for Class A surfaces

- Active surface preparation with a tremendous impact on tryout

- Convenient manufacturing preparation for automated production

- Short run times on machines

- Virtual machine technology for maximum reliability

- No reworking of parts with Class A manufacturing quality

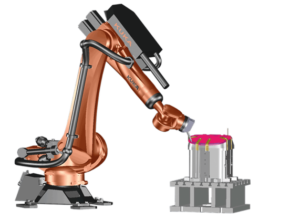

- Perfect for 6-axis robots as well

- Reliable planning with integral MES solution

- Low-cost access to Tebis CAD/CAM technology

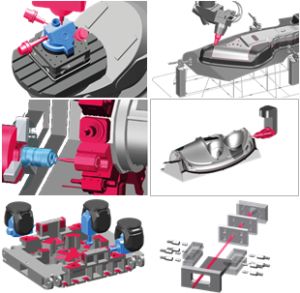

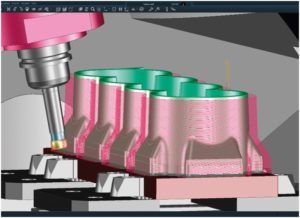

- 3 and 5-axis milling

- Drilling

- Turning

- Laser cutting

- Laser hardening

- Trimming

- Hammer peening

- Sinker and wire EDM

- High complexity

- Large part size

- Enormous data volume

- Robust calculation algorithms

- Efficiently replace geometries without losses

- Break assemblies in individual manufacturing files

- Automatically optimize surface quality

- Surface quality optimized in Tebis is retained in the target system

- NC-manufactured free-form surfaces from optimal CAD data

- Powerful functions for designing, modeling, repairing, morphing and reverse engineering

- For highly demanding manufacturing of exterior surfaces

- Specialized CAD functions for active surfaces

- Exact surfaces fully designed in detail in the die

- Automatically create transition-free pressure surfaces and radius areas adjusted for pressing conditions

- Manufacture dies without NC attributes

- Minimal tryout work after NC machining

- Specialized CAD functions

- User-friendly preparation of manufacturing models for NC processes

- Prepare automated NC programming

- Optimized surface quality

- Continuously optimized Tebis NC algorithms

- Minimized idle travel with maximized cutting performance

- High-quality technical support for HFC and HPC cutters for roughing, prefinishing and finishing

- Special contact algorithms and path layouts with full-cut avoidance

- Process libraries reflect the actual manufacturing environment

- Geometric and technical properties of tools, machines and clamping devices can be called up at any time

- Collision avoidance during calculation of NC paths

- Automatic reduction of milling areas and 5-axis avoidance

- Integral machine simulation

- Direct transfer of high-quality CAD surfaces to NC programs

- Calculate NC paths on mathematically exact surfaces

- Influence finish quality with adjustable NC point distribution

- No tedious manual reworking

- 3 to 5-axis machining centers

- NC-programming of articulated robots with six or more axes

- Proleis MES system is integrated in Tebis and the user interface

- Comprehensive organization, planning and control of manufacturing projects

- Integrated machine and operating data acquisition for current and realistic information

- Software package in various performance levels

- Extensive add-on portfolio

- Floating-licenses for “on-the-fly” workstations (shareable)